The byproduct of any process that uses a saw or other tool to pulverize wood is the sawdust. This includes chopping, sanding, drilling, grinding, and more. Mulch is another option to clay when it comes to cat litter, and it can also be used in the production of particleboard, which is used in the traditional production of furniture and paper made from wood pulp. The most important function that sawdust serves is that of fuel after it has been processed into pellets. Creating wood pellets from sawdust is a relatively new field that offers excellent employment prospects. Sawdust is the raw material used to make wood pellets, which are currently manufactured in hundreds of countries around the world.

Uses of Sawdust Pellets

- Sawdust pellets made from waste wood are an efficient form of fuel that can effectively take the place of more conventional fossil fuels such as gas, coal, gasoline, and so on. It is possible to cook meals at home by lighting them on fire on a stove.

- Warm up the home, the classroom, the hotel, or the greenhouse on the farm.

- Production of sawdust pellets at an industrial scale has the potential to serve as a substitute for coal in thermal power plants.

- As an alternative to clay for use as cat litter.

- Additionally suitable for use as horse bedding, in addition to that of cows, chickens, dogs, and a variety of other animals.

- Other applications are just waiting to be found.

What are the Steps Involved in Turning Sawdust into Wood Pellets?

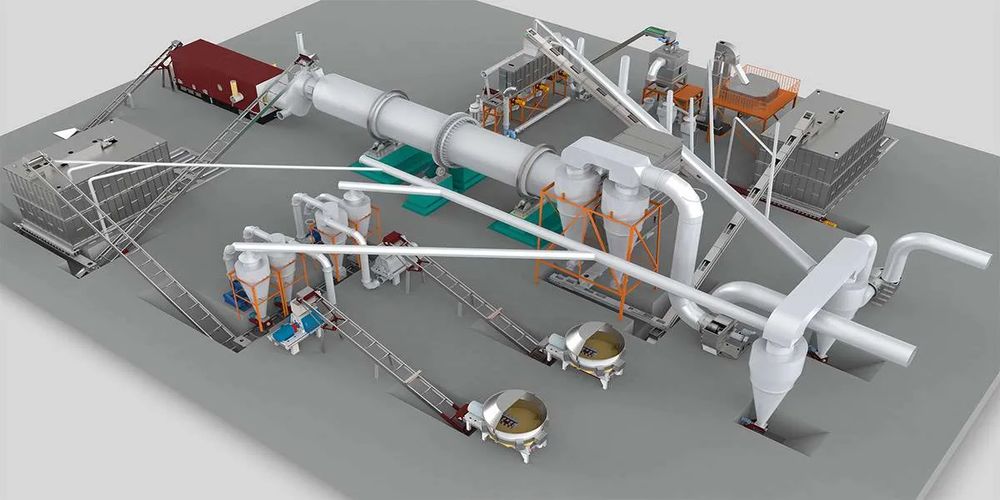

After figuring out how to turn sawdust into wood pellets, the next logical step is to find out what can be done with those pellets once they’ve been made. The method is not overly difficult to execute. The following is an explanation of the wood pellet production line:

Prepare the ingredients from scratch. In most cases, sawdust is of a fine enough consistency to be used in pellet production. The first thing that needs to be done is to moisten the sawdust by soaking it in water until it reaches a moisture content of between 8 and 15 percent, which is the optimal range for pelletizing. There are exceptions to this rule if the raw material is wood chips. Sawdust should be fed into the pellet machine for wood in a measured fashion. In order to maintain consistent feeding of raw material during large-scale pellet production, a screw feeder is required.

Sawdust pellets, once pelletized, have a high temperature that makes them unsuitable for direct packing. Therefore, pellet coolers should be used to cool them down.

After that, the pellets are put through a vibrating sieve, separating the usable pellets from the broken or otherwise unusable ones and collecting the latter and the powder.

After completing the preceding steps, pellets are ready to be packed using a pellet packing machine.

Conclusion

You now know how to make pellets out of waste wood sawdust; considering starting your own pellet-making business, are you interested in doing so now? In the event that you require additional information, you can comment below, and we will be happy to answer your questions.